About us

The history of Galvanizacija dates back to 3 September 1986, when the company was founded by Mato Bartolović, who previously worked as galvanizing manager in Končar, a renowned Croatian company, for over 20 years.

Initially, the business was conducted from a small space within his house. Later it moved to somewhat larger rented business premises, where it remained until 2003, when it moved to a newly built facility in the new industrial park in Požega.

Soon after, due to high market demands, the facility was extended, getting a warehouse for plated elements, a warehouse for chemicals, wastewater pools etc.

Galvanizacija has at its disposal two fully automated lines for zinc electroplating, namely:

-

A line for hanging goods on racks

-

A line for bulk goods in barrels

Continuous wastewater and air treatment is performed in parallel with zinc electroplating technology.

After Mato Bartolović passed away, the business was taken over by his children Krunoslav Bartolović and Marija Galović, with her husband Tomislav Galović as lead technologist. They continued the business operations through the company

SUSRET d.o.o.

Dubrovačka 83

34 000 Požega

OIB: 49925967593

Zinc electroplating

From a weakly acidic chloride electrolyte for zinc electroplating, as used by Galvanizacija GOLD, it is possible to plate items made of steel, alloy steel, brass, copper, copper alloys…

The thickness of plated layer depends on the requirements of the customer or can be predetermined by technical documentation.

The zinc layer is further protected by a top-quality trivalent passivation, i.e. a process during which a thin chromium film forms on the zinc surface, giving zinc higher resistance and better appearance.

Rack plating

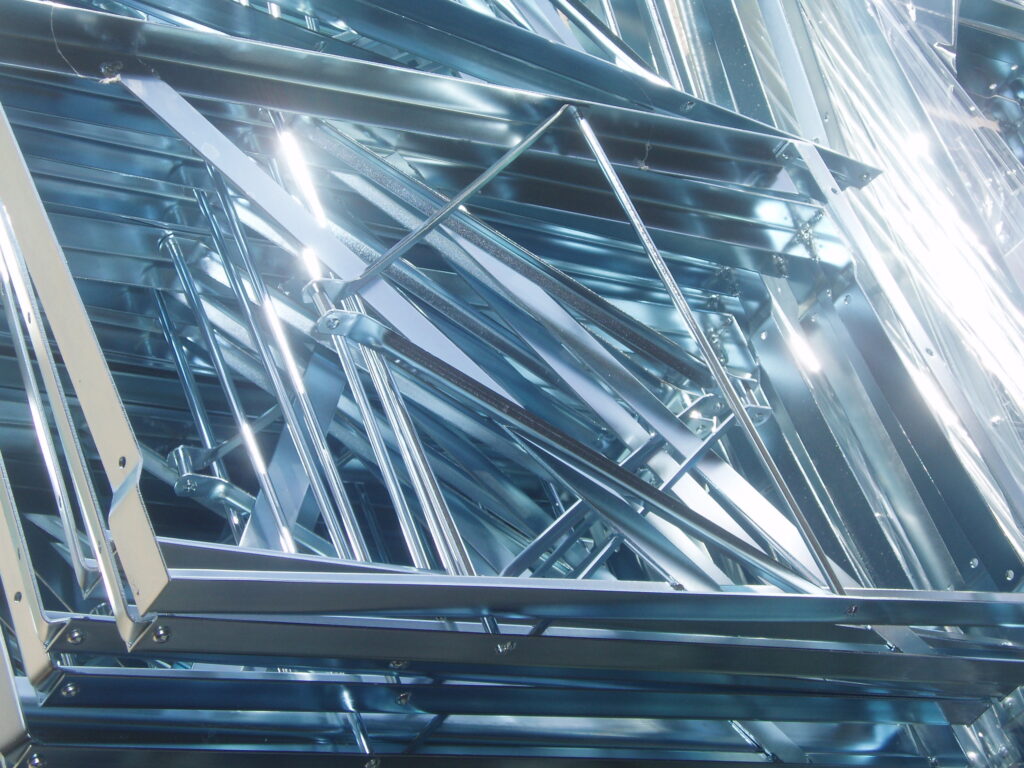

A line for hanging goods on racks is fully automated, i.e. it is equipped with the latest Siemens PLC system.

The line is fitted with two conveyors that participate in the process of galvanization synchronously, and they are mutually connected via radio.

The maximum dimensions of objects to be plated are 2.70 m x 1.30 m x 0.50 m (L x H x W), which allows us to plate bulky goods such as shopping carts, chairs, etc. The objects over 1.30 m high can be processed by flipping them, in which case the maximum height to be plated is 1.85 m.

Barrel plating

The barrel line is also fully automated, with the capacity of maximum 100 kg per barrel. It is used for plating bulk materials such as screws, springs, nuts, nails and similar.

At the end of the line there is a new centrifugal dryer that meets the highest standards for drying plated goods.

Ecology

During the technological process of zinc electroplating, we perform continuous wastewater and air treatment. We address this issue from the moment of choosing the chemicals. The chemicals we use are eco-friendly, they do not contain cyanides or complexants, and they are all produced by EU manufacturers.

The process of wastewater treatment is fully automated and it consists of neutralisation of acidic and alkaline waters, chromate reduction and hydroxide precipitation of metals in form of galvanic sludge, which is then filtered through a filter press, and the filtered waste is disposed in accordance with regulatory provisions and regulations.

Continuous air treatment is carried out by collecting all volatile components (vapours) through the ventilation system, and taking them to the central unit, where they are neutralized by rinsing, and then released into the atmosphere. The vapours produced in the process are being collected at two levels. The first level includes the baths themselves, where heavier vapours are collected, while the remaining lighter vapours are collected at the second level. The air treated this way that is released into the atmosphere adheres to all applicable laws and regulations.

Address and Contacts

GALVANIZACIJA GOLD

Obrtnička 18

34 000 Požega

Contact persons: